What is a threaded flange?

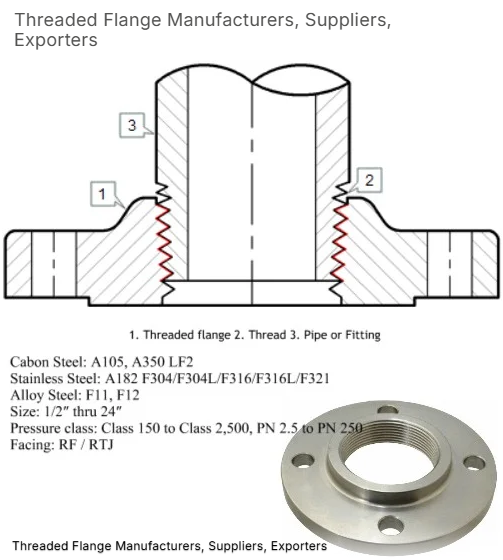

A threaded flange is a type of pipe flange with internal threads on its bore, allowing it to be screwed onto a pipe with corresponding external threads, eliminating the need for welding for connection.

SHUANGNENG flanges is a professional manufacturer and exporter of Threaded or Threaded Flanges with our own precision machining facilities. We manufacture threaded flanges in accordance with ANSI B16.5, DIN standards and EN1092-1 in sizes ranging from 1/2“ to 24” NPs.We also manufacture and supply carbon steel flanges as well as alloy steel flanges for high pressure and high temperature applications. We manufacture threaded flanges in carbon steel, stainless steel, high nickel alloys, duplex/super duplex, cupro-nickel steel, titanium alloys and specialty alloys.

Our flange production process includes suitable heat treatment and chemical and mechanical property tests. We have CNC and normal lathes to process all kinds of threaded flanges.

|

Product |

Threaded Flanges, as per ASTM A182 |

|

Materials |

Carbon steel: ASTM A105, A181, ASTM A516 GR.60, GR.70, ASTM A694 F42, F46,F52,F56F60,F65,F70,ST37, ST45.8,C22.8,S235,S235JRG2,P235GH,P245GH,P250GH,P265GHP355GH,S355J2,16MN, 20MN, Q235, 20#,CT20, SS400. Stainless steel: ASTM A182 F304,F304L,F316, F316L,F321, F321H,F304H, F316H, F347H,1.4301, 1.4306,1.4401, 1.4404,1.4541, 1.4571, SUS304, SUS316. Alloy Steel: ASTM A350 LF2,CL1/CL2, ASTM A182 F5, F9, F11, F12,F22,F91. Duplex Steel:s31803/F51/S32205/F60/1.4462 Super Duplex:S32750/F53/1.4410/S32760/F55 /1.4501 |

|

Size |

1/2" to 60", DN 15 tO DN 1500 |

|

Face Type |

Flat Face Flange (FF) Raised Face Flange (RF)Ring Joint Flange (RTJ)Lap Joint Flange Male and Female Flange (M&F)Large and Small Tongue and Groove Flange (T&G) |

|

Product Type |

Forged Flanges, Blind Flanges, Spectacle Blinds, High Hub Blinds, Orifice Flanges, Slip-on Flanges, Socket Weld Flanges, Weld Neck Flanges, Flat Flanges, Lap Joint Flanges, Threaded Flanges, Reducing Flanges, Weld Neck Flanges Series A or B, Square Flanges, Groove &Tongue Flanges, Long Neck Weld Flanges, Screwed Flanges, Ring Type Joint Flanges, Flange Facing Type & Finish, Spades and Ring Spacers (part of flange connection), Weld Flange /Nipo Flange, Expander Flange |

|

Surface Treatment |

Anti-Rust Oil, Painting ( Black, Yellow),Galvanizing, Power Coating |

Threaded Flange Types

There are two types of threaded flanges. One is to seal the two pipe ends with a certain sealing surface and a lens pad. This type of flange is mostly used for ammonia production. But it has been used less recently, and the lens pad has been replaced by a metal ring.

The other type is the same as a normal flange, sealed with two flange sealing faces.

Facing Types

There are two facing types for threaded flange, raised face flange and ring joint flange.

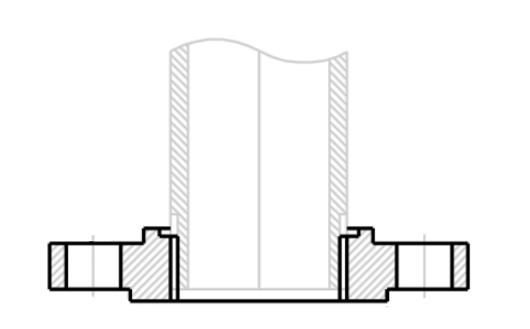

Raised Face Threaded Flange

When the gasket surface area is above the bolted line of the flange, the raised face flange is easily identified. It is compatible with a wide range of gaskets, from flat to semi-metallic and metallic types, either ring or full.

The main scope of a raised face flange design is to concentrate the pressure of the two mating flanges on a small surface and increase the strength of the seal.

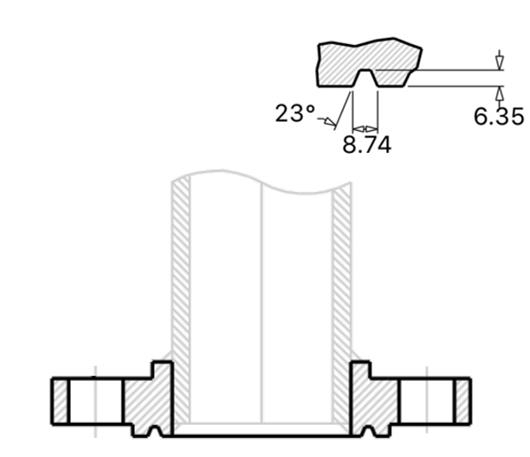

The height of the raised face surface depends on the flange pressure level, for example, for pressure classes 150 and 300, the height is 1.6 mm or 1/12 inch, and for the 400 to 2500 level, the raised face height is about 6.4 mm, or 1/4 inch.

RTJ Threaded Flange

The ring joint flange has a circular groove to accommodate the ring joint gasket, which can be used when metal to metal seals are required. Especially in conditions for high pressure and high temperature.

Application in Special Circumstance

Threaded flanges are used where it is difficult to weld or cannot be welded, such as threaded flanges used to protect the galvanized layer of pipes. In addition, It should not be used on pipes with repeated temperature fluctuations or above 260 ℃ and below -45℃ as well.

In ASME B31.3 standard it defines:

Where steel pipe is threaded and used for steam service above 250 psi or for water service above 100 psi with water temperatures above 220° F, the pipe shall be seamless and have a thickness at least equal to schedule 80 of ASME B36.10.

How to install a threaded flange?

Installation Guide for Threaded Flanges

1. Prepare the Pipeline. ...

2. Apply Sealing Material. ...

3. Connect the Flange. ...

4. Tighten the Flange. ...

5. Align the Flanges. ...

6. Install Gaskets. ...

7. Install Bolts. ...

8. Final Tightening.

Copyright © 2024 Zhejiang Shuangneng Steel Industry Co., Ltd. All Rights Reserved. Links Sitemap RSS XML Privacy Policy